No, driving any distance with a broken tire belt is extremely unsafe. The tread could detach causing sudden deflation and loss of control. Have it towed and replaced immediately.

Motoring down the highway, your steering wheel shudders as a loud pop erupts from your rear tire. Glancing back reveals a large bubble forming on the sidewall surface. You’ve experienced a broken steel belt determined to derail your drive. But what should you do about this broken structural component before it leaves you stranded?

While a broken tire belt puts you in a bind, learning proper tire belt protocols helps you make the safest choice before things deteriorate further. Let’s get rolling again!

The Critical Role and Anatomy of Steel Tire Belts

Radial tires utilize steel belts just under the tread to provide structural reinforcement:

- Belts resist deformation from inflation pressures and loads

- Cords add rigidity minimizing sidewall flexing

- They enable stable high-speed handling

These bands interlace in specifically engineered orientations:

- Most passenger tires have dual steel belts in a crisscrossed bias pattern

- Heavy duty tires feature 3 belts plus nylon cap plies for added durability

- Belts distribute stresses uniformly for smooth predictable performance

However various abuses can fatigue and fracture these vital steel cords leading to broken tire belts.

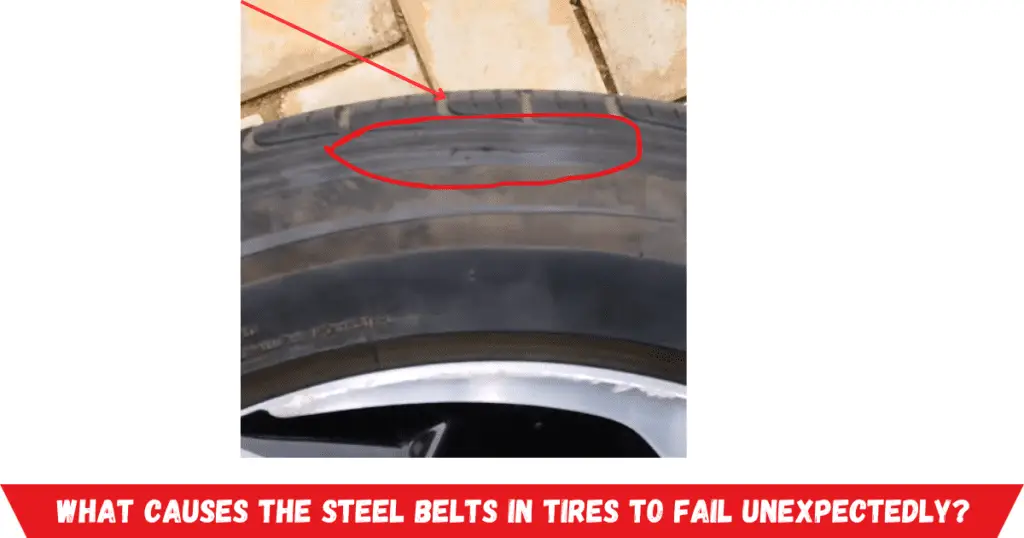

What Causes the Steel Belts in Tires to Fail Unexpectedly?

Many factors progressively damage hidden belts until they abruptly snap, including:

Impact Damage – Curbing, potholes, and debris strikes can fracture belt cords, allowing air and moisture to corrode the steel leading to sudden separation later.

Improper Inflation – Underinflation overstresses belts through excessive sidewall flexing. Over-inflation reduces cushioning from road impacts.

Suspension Faults – Damaged shocks, struts, and bushings transmit more vibration through the tire structure straining components.

Rotations and Balancing – Skipping rotations cause uneven tread wear distributions that put greater stress on belts in vulnerable tire positions.

Embedded Debris – Foreign objects like nails and screws often break belts when tires are penetrated and then plugged because they don’t show on visual inspections.

Age and Weathering – Years of use slowly work hard and corrode steel cords until they lose structural integrity and snap.

Watch for signs of damage and replace aging tires early. This ensures belts stay intact rather than coming apart unexpectedly.

Warning Signs a Tire Belt is About to Break

Look for these subtle early indicators of impending tire belt failure:

- Minor sidewall cracking and crazing visible upon close inspection

- Small bumps forming under the tread pointing to cord separation

- Tread wearing unevenly causing sloppy handling on that corner

- Wheels running out of balance frequently as debris shifts

- Vibration emerging from one corner, often worse at highway speeds

- Tire avoiding sitting fully flush when stationary

Don’t dismiss these minor symptoms – catch belt issues early before a major detachment leaves you stranded.

Full Tire Belt Detachment and Blowout Dangers

Once fully fractured, continuing driving on a broken belt is extremely dangerous:

- Air loss as the loose belt fully penetrates the sidewall internally

- The tread peeling completely off in sheets at high speed

- Sudden blowouts as the broken belt bubble bursts violently

- Reduced stability and handling from the badly deformed tire shape

- Damage to fenders, wheels, and chassis from flying tread chunks on disintegration

- Fire risk from friction igniting grease and overheated components

Don’t play with fire – replace fully detached belts immediately. The tire will self-destruct rapidly.

Temporary Emergency Repairs for Broken Tire Belts

For very minor belt damage like small sidewall cracks, temporary remedies may provide enough reinforcement to limp to a tire shop:

- Rubber cement sealing minor cracks and crazing

- Tire foam fillers injected into the void to delay air loss

- Tire sealants to quickly plug a puncture and solidify debris

- Internal patch/plugs to line the inner sidewall surface

But extensive sidewall separation, large bubbles, or tread lifting means the belt is too far gone. Call for towing rather than risk a dangerous failure in motion. Don’t take chances!

How to Safely Replace a Tire with a Broken Belt

Follow these step-by-step procedures to avoid damage or injury:

- Position the vehicle fully off the road on solid, level ground away from traffic

- Set the parking brake and chock both sides of the wheel diagonally opposite the flat

- Loosen each lug nut one full turn before jacking – Never remove completely until supported

- Jack the vehicle safely using the reinforced door jam points until the tire clears the ground

- Finish removing lug nuts and pull the tire directly away from yourself for stability

- Inspect exposed belt and inner sidewall surfaces for any hidden damage before reinstalling

- Reinstall the spare, hand tightening lugs evenly, and lower the vehicle before fully torquing

- Finally torque the lugs properly in a star pattern to avoid wheel, stud, and rotor damage

Rushing tire changes risks wheel components separating at speed. Work cautiously to ensure safety.

Can Broken Tire Belts be Prevented Through Maintenance?

You can minimize sudden belt detachments by:

- Performing complete tire inspections looking for sidewall defects during each rotation

- Having tires dismounted periodically for internal inspection after puncture repairs

- Checking inflation pressures frequently – improper inflation strains belts

- Balancing and aligning regularly to distribute wear patterns evenly

- Rotating to shift the load to prevent focusing strain only on front or rear axles

- Avoiding hazards like curbs and road debris which damage hidden belts

- Replacing tires early once 6 years old regardless of tread depth

With consistent care, your tires’ internal bands can keep their integrity for more miles.

Frequently Asked Questions

Let’s recap some key facts on dealing with busted belts:

What happens when a steel tire belt breaks?

The reinforcements rupture leading to bulges, bubbles, sudden air loss, and tread detachment. This causes vibration, wobbling, and handling loss often at highway speed.

How can I identify different types of belt damage?

Look for warning signs like shifting tread sections, faint cracks, and small bulges to identify belts starting to separate internally before total detachment.

Is it ever safe to drive with a broken belt?

No, any sign of belt damage makes the tire unreliable and likely to catastrophically fail suddenly. Replace immediately before use.

What does a detached tire belt sound like?

Listen for popping as bubbles burst, loud rumbling from bulged sections sticking out, and flapping from portions of tread completely separating from the belts while driving.

How often should I have my tire belts inspected?

Check belt condition closely whenever rotating tires and having wheels removed for any reason. Budget periodic dismounting for internal inspection of aging tires to catch issues early.

Conclusion

While quietly reinforcing your tires, broken belts make plenty of noise you can’t ignore. Learn their sounds and symptoms to avoid the hazards of sudden air loss blowouts down the road. With frequent attention and care, you can catch belt issues before they leave you stranded. Don’t let broken bands derail your travels – safety first!